About Me

Hi there! I'm Spenser.

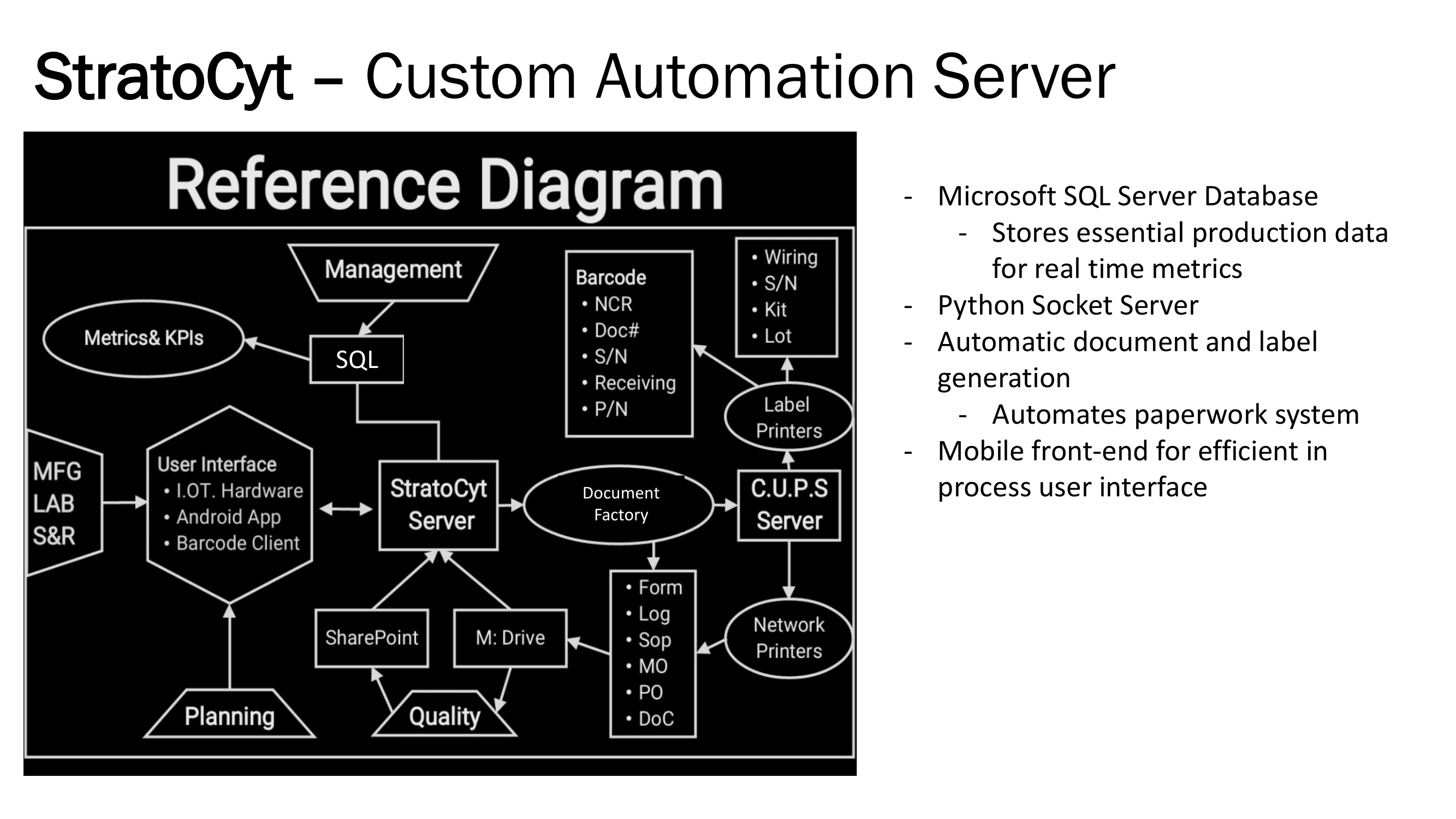

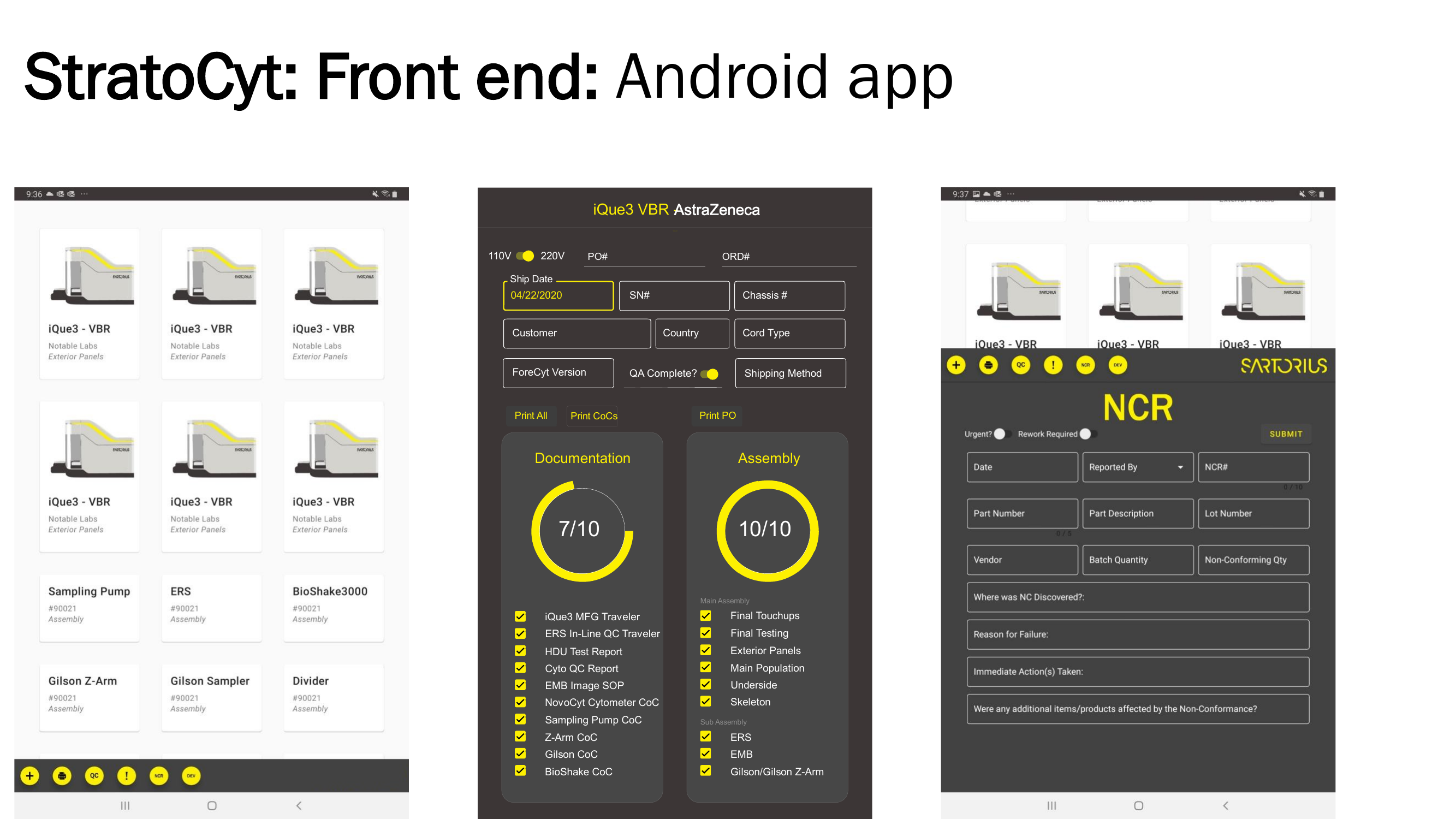

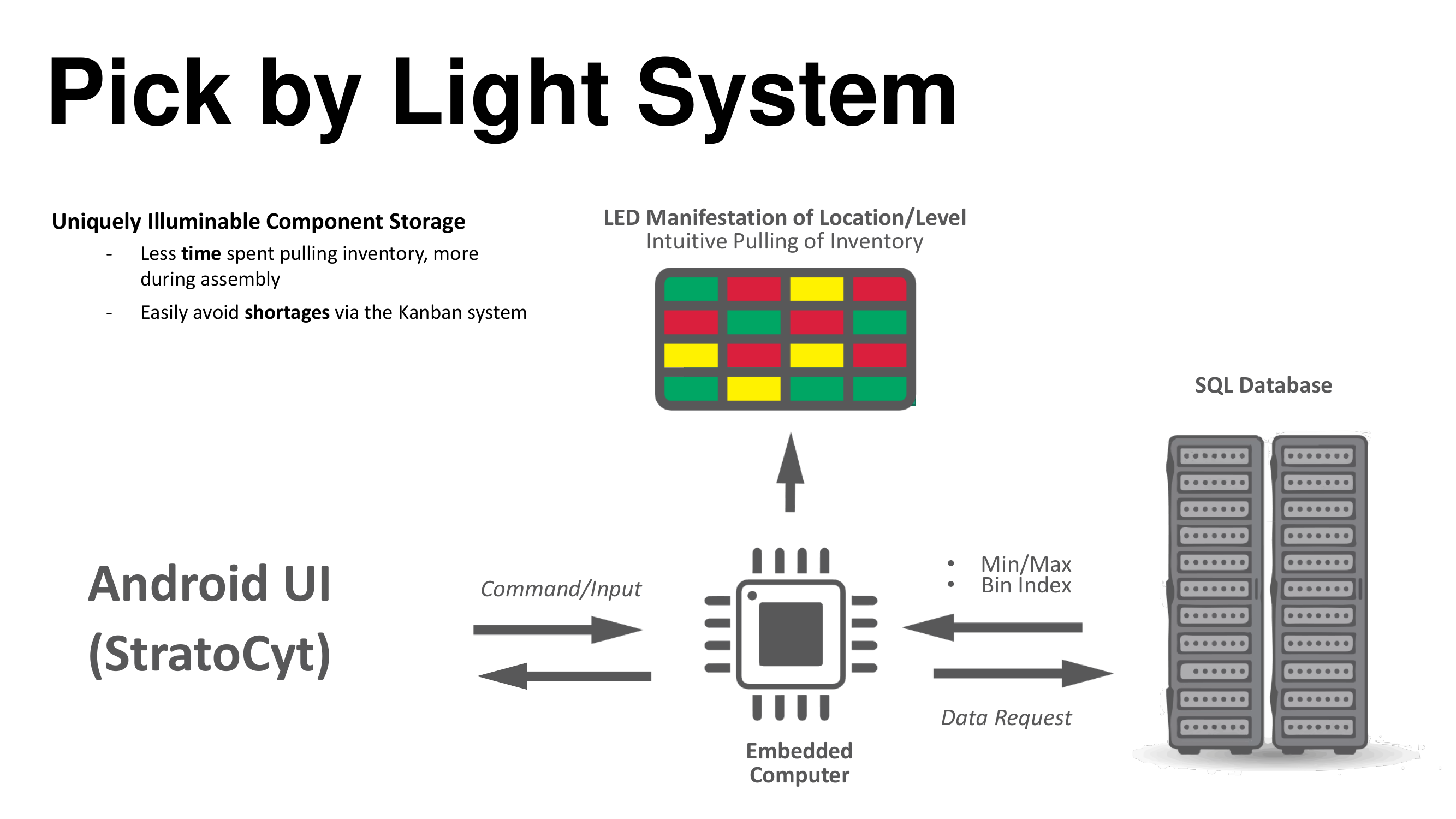

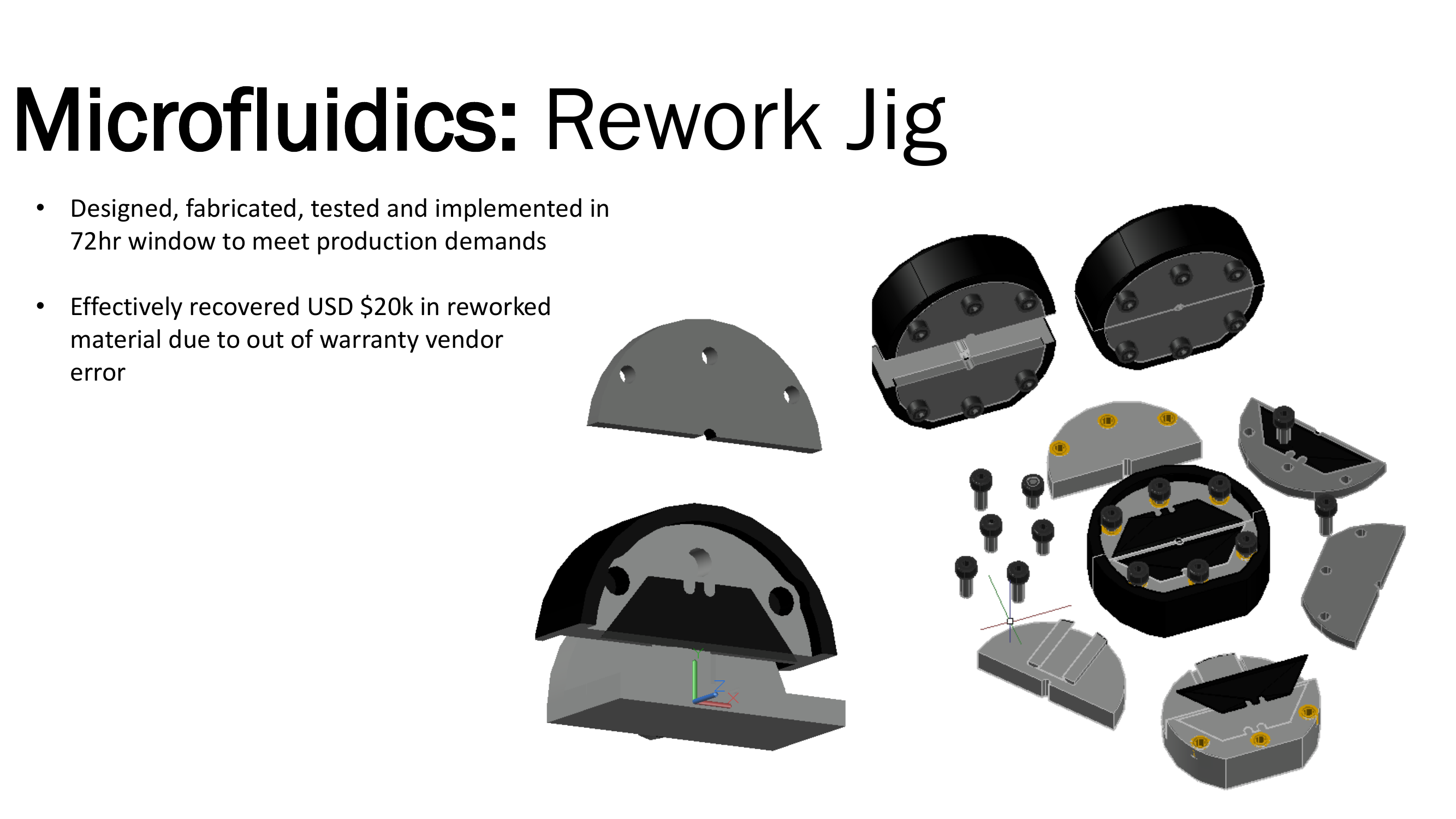

I'm a versatile engineer with a passion for robotics, software, embedded systems, and full stack development. I bring to the table a Mechatronics Engineering degree from Northeastern University (Class of 2025) and 7 years of full-time industry experience at companies like Symbotic and Walmart Advanced Systems & Robotics. My career began in 2018 as a Manufacturing Technician at Sartorius (Medical Devices) and transitioned into engineering at Owl Labs (Consumer Hardware).

My skillset includes technical depth in Software Engineering, Real-Time Embedded Firmware, Mechanical Design, EE, DevOps, and AI. I've successfully delivered mission-critical systems on time and within budget, currently running on thousands of robots around the globe!

Outside of the office, I love camping, surfing and going on road trips with my friends!